DETERMINTION OF DUCTILITY

DEFINTION The ductility of bituminous material is the distance in centimeters to which it will elongate before breaking when a briquette specimen of the materials is pulled at a specified speed and at specified temperature.

APPARTUS Testing machine Mould made up of brass Water bath preferably with a thermostat, 10lit capacity and maintained with in 0.10C of the specified temperature Thermometer 2500C capable of reading up to 0.010C.

PROCEDURE Unless otherwise specified this test shall be conducted at a temperatures of 27 + 0.50C and at a rate of pull of 50 + 2.5mm /min. Melt the bitumen to be tested to a temperature of 75 to 1000C above its approximate softening point till it becomes fluid. Assemble the mould on a brass plate and coated on all the sides with a mixture glycerin and dextrin of equal parts to avoid sticking of the material. Fill the mould until it is more than level full. In filling the mould, pour the material in a thin stream back and forth from end to end of the mould. Leave it to cool room temperature for 30 to 40 minutes and than place it in water bath maintained at a specific temperature for 30 minutes. Cut off excess bitumen by means of hot straight edged putty knife level full. Place the brass plate and mould with briquette specimen, in the water-bath and keep at the specified temperature for about 85 to 95 minutes.

Remove the briquette from the plate, detach sidepieces and test the briquette immediately.

While the test is being conducted, make sure that the water in the tank of the testing machine covers the specimen above by at least 25mm and is maintained continuously with in +0.50C of specified temperature. Attach rings at each end of the clips to the hooks in the testing machine and pull the two clips apart horizontally at a uniform speed as specified until the briquette ruptures. Measure the distance in centimeters through which the clips have been pulled to produce rupture. At least three determinations shall be made for each test.

REPORT Report the average of three normal tests as ductility of the sample, provided that, the three determinations be with in + 5% of their mean value. If the value of three determinations do not lie with in + 5% of their mean but the two higher value are with in + 5% of their mean, then record the mean of the two higher values as the test result. PRECISION The duplicate test results should not differ by more than the values given below Repeatability Reproducibility 10% of mean 20% of mean PRECAUTION In filling the mould care shall be taken to see that no air bubbles shall be formed, and not to disarrange the parts and thus distorting the briquette.

Aggregate Crushing Value Test

The objective of this test is to:

- Determine the aggregate crushing value of coarse aggregate

- Assess suitability of coarse aggregates for use in different types of road

Apparatus

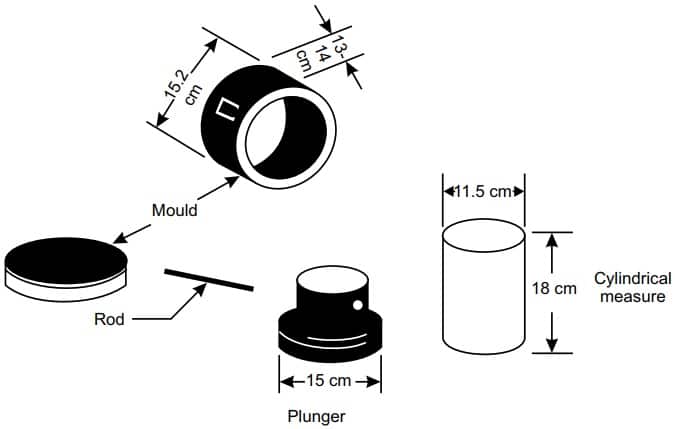

- A steel cylinder 15 cm diameter with plunger and base plate.

- A straight metal tamping rod 16mm diameter and 45 to 60cm long rounded at one end.

- A balance of capacity 3 kg readable and accurate to one gram.

- IS sieves of sizes 12.5mm, 10mm and 2.36mm

- A compression testing machine.

- Cylindrical metal measure of sufficient rigidity to retain its from under rough usage and of 11.5cm diameter and 18cm height.

- Dial gauge

Sampling of Aggregates

Coarse aggregate passing 12.5mm IS sieve and retained on a10mm IS sieve are selected and heated at 100 to 110°C for 4 hours and cooled to room temperature.

The quantity of aggregate shall be such that the depth of material in the cylinder , after tamping as described below shall be 10 cm. The appropriate quantity may be found conveniently by filling the cylinder.

Measure in three layers of approximately equal depth, each layer being tamped 25 times with the tamping rod and finally leveled off using the tamping rod as straight edge.

Care being taken in the case of weaker materials not to break the particles. The weight of the material comprising the test sample shall be determined (weight A) and the same weight of sample shall be taken for the repeat test.

Procedure of Aggregate Crushing Value Test

- Put the cylinder in position on the base plate and weigh it

.

- Put the sample in 3 layers, each layer being subjected to 25 strokes using the tamping rod. Care being taken in the case of weak materials not to break the particles and weigh it (W1).

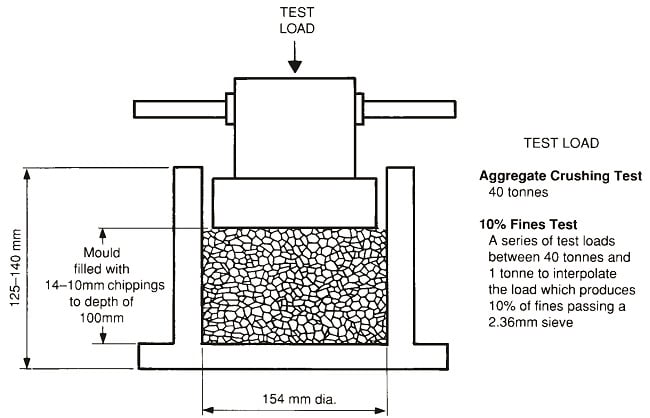

- Level the surface of aggregate carefully and insert the plunger so that it rests horizontally on the surface. Care being taken to ensure that the plunger does not jam in the cylinder.

- Place the cylinder with plunger on the loading platform of the compression testing machine.

- Apply load at a uniform rate so that a total load of 40T is applied in 10 minutes.

- Release the load and remove the material from the cylinder.

- Sieve the material with 2.36mm IS sieve, care being taken to avoid loss of fines.

- Weigh the fraction passing through the IS sieve (W2).

Calculation of Aggregate Crushing Value

The ratio of weight of fines formed to the weight of total sample in each test shall be expressed as a percentage, the result being recorded to the first decimal place.

Aggregate crushing value = (W2 x 100) / (W1-W)

W2 =Weight of fraction passing through the appropriate sieve

W1-W =Weight of surface dry sample.

The mean of two result to nearest whole number is the aggregate crushing value.

Result

The aggregate crushing value of the given sample=

Aggregate Crushing Values for Roads and Pavement Construction

The table below shows limits of aggregate crushing value for different types of road construction:

| Types of Roads / Pavements | Aggregate Crushing Value Limit |

| Flexible Pavements | |

| Soling | 50 |

| Water bound macadam | 40 |

| Bituminous macadam | 40 |

| Bituminous surface dressing or thin premix carpet | 30 |

| Dense mix carpet | 30 |

| Rigid Pavements | |

| Other than wearing course | 45 |

| Surface or Wearing course | 30 |

TEST FOR ORGANIC IMPURITIES IN FINE AGGREGATE

The aggregate must be checked for organic impurities such as decayed vegetations, humus, and coal dust, etc. Colour test is a reliable indicator of the presence of harmful organic matter in aggregates except in areas where there are deposits of lignite.

Procedure:

- a) Fill a 350 ml clear glass medicine bottle upto 75 ml mark with a 3% solution of caustic soda or sodium hydroxide.

A 3% solution of caustic soda is made by dissolving 3 gm of sodium hydroxide (which can be purchased from any local laboratory chemicals shop) in 100 ml of clean water (preferably distilled water). The solution should be kept in glass bottle tightly closed with a rubber stopper. Handling sodium hydroxide with moist hands may result in serious burns. Care should be taken not to spill the solution for it is highly injurious to clothing, leather and other materials.

- b) The representative sands sample is next added gradually until the volume measured by the sandy layer is 125 ml. The volume is then made up to 200 ml by the addition of more of the solution. The bottle is then corked and shaken vigorously and allowed to stand for 24 hours.

c)At the end o f this period, the colour of the liquid will indicate whether the sand contains a dangerous amount of matter or not. A colorless liquid indicates clean sand free from organic matter. A straw-colored solution indicates some organic matter but not enough to be seriously objectionable. Darker colour means that the sand contains injurious, amounts and should not be used unless it is washed and a retest then shows that it is satisfactory.

TEST FOR SILT CONTENT OF FINE AGGREGATE

It is important to use clean aggregate for concrete. If the aggregates are coated with dirt, silt or clay, it will result in a poor concrete because the dirt will prevent the cement from setting and also weaken the bond between the aggregates and the cement paste.

Further owing to their fineness and therefore large surface area, increases the amount of water necessary to wet all the particulars in the mix, this also resulted more shrinkage of concrete. As determine with the given field test, the sand shall not contain more than 8% of 1/10 silt.

Procedure:

(a) Fill a measuring cylinder with a representative sand (fine aggregate) sample up to 100 ml mark and add clean water up to 150 ml. To perform this test, more correctly better dissolve a little salt in the water (1 tea spoonful to 250 ml is the right proportion).

(b) Shake the sample vigorously for one minute and the last few shakes being in a side wise direction to level of the sand.

(c) Allow the cylinder to stand for three hours during which time any silt present will settle in a layer on the top of the sand and its thickness can be read off on the cylinder itself. The sand shall not contain more than 8% of silt. Note: In performing this test the sand sample should not dry. Glass measuring cylinder capacity should be 200 ml.

TEST FOR MOISTURE CONTENT OF CONCRETE AGGREGATE

The various stages in which the aggregate may exist are

(a) over dry (b) air dry (c) saturated surface dry (d) damp or moist. On the construction site, the sand (fine aggregate) usually carries some free moisture. Total internal moisture content of an aggregate in the saturated surface dry condition may be termed as “Absorption capacity” although it is sometimes referred to simply as the absorption. The amount of water required to bring an aggregate from the air dry condition to the saturated surface dry condition is termed as “effective absorption”. The absorption is determined by finding the weight of a surface dried sample after it has been soaked for 24 hours and again finding the weight after the sample has been dried, the difference in weights, expressed as a percentage of dry sample weight, is the absorption capacity.

Procedure:

(a) Take about one kg of representative sample of sand (fine aggregate) in a suitable size tray. Fully immerse this sand sample in clean water for 24 hours.

(b) After 24 hours of immersion take about 500 gm of representative wet sand sample. Dry this sand in saturated surface dry (SSD) condition either in air or heating in a fry pan. Take the weight (A) of SSD sand sample in fry pan and dry it fully in gentle heat. After drying take its weight (weight B).

(c) Take about 500 gm representative site sand sample. Take its weight (weight C) and fully dry it in a fry pan. Take the dry weiht (weight D).

Calculations: 1. Water absorption (%) = [A-B]/B x100

- Total moisture in site sand % = [C-D]/D x100

- Surface moisture in site sand (%) = Total moisture in site sand % – Absorption of site sand %

If the result is in negative, it means the sample does not contain any surface moisture and in it balance absorbed water is to be added to make the site sand in SSD condition.

2/10

Note: (A) For obtaining the SSD condition of sand, it should be gently heated in a fry pan, mean while stirring with a glass rod until the surface moisture disappears. This is apparent when the sand loses its shining wet appearance and becomes dull, or when it just attains a free running condition. The end point of aggregate SSD condition could be found by practice. If the sand is heated beyond the SSD condition some of the absorbed moisture will also dry and then the SSD weight of aggregate will not be correct, and the obtained absorption result will not be correct.

(B) The same procedure with appropriate changes in the size of the sample and dimension of the container may be applied to obtain moisture content of coarse aggregate.

TEST FOR BULKING OF SAND

Dry and fully saturated sand does not bulk. As the sand becomes finer the bulking of the sand increases. The bulking of sand is caused by the film of moisture which tends to keep the particles of sand apart.

Procedure Method

- Put sufficient quantity of site sand loosely into a suitable conbtainer until it is about two-third full. Level off the top of the sand and push a steel rule vertically down through the sand at the middle to bottom, measure the height. Suppose this is `x’ cm.

Empty the sand out of the container into another container where none of its is lost. Half fill the first container with clean water. Put back about half the sand and rod it with a steel rod, about 6 mm in diameter, so that its volume is reduced to a minimum. Then add the remainder sand and level the top surface of the fully saturated sand. Measure its depth at the middle with the steel rule suppose this is `y’ cm.

Percentage bulking =[x/y -1] x 100

Method 2. In a 250 ml measuring cylinder, pour the damp site sand, consolidate it by staking until it reaches the 200 ml mark.

Then fill the cylinder with the clean water and stir the same well (the water shall be sufficient to submerge the sand completely), It will be seen that the sand surface is now below its original level. Suppose the surface is at the mark of y ml, the percentage of bulking of sand due to moisture shall be calculated from the formula.

Percentage bulking =[200/y -1] x 100

TEST FOR SPECIFIC GRAVITY OF AGGREGATE

The specific gravity of a substance is the ratio of the unit weight of the substance to the unit weight of water. A representative aggregate sample in SSD condition is obtained by quartering and the following weights are used in the tests for the various sizes of aggregates.

Less than 4.75 mm : 500 to 700 gm

4.75 mm to 10 mm : 1000 to 1500 gm

10 mm to 20 mm : 1500 to 2000 gm

20 mm to 40 mm : more than 2000 gm

Procedure:

(a) Take a suitable size jar, the top open side of which have flange, so that a glass plate may be put on it.

(b) The jar should be filled with clean water upto the flange and slide on it the glass plate. If there is any air bubble, which can be seen from top of glass plate, then the jar top should be filled with more water. There should not be any air bubble. Take the weight of jar fully filled with water and upon it glass plate (weight A).

- About half empty the jar fill it with known weight of SSD aggregate sample weight (B). As mentioned at b, fill the jar upto the top and putt glass plate on it. There should not be any air bubble. Take its weigh (weight C). Specific gravity on SSD basis = B/ [B-(C-A)]

TEST FOR BULK DENSITY OF AGGREGATE

Bulk density is the weight of a unit volume of aggregate, usually stated in kg per litre on room dry basis in estimating quantities of materials and in mix computation, when batching is done on a volumetric basis.

Concrete material proportion by weight can be converted to proportions by volume, by dividing with the bulk density of the materials available for use at site. The bulk density of cement may be taken 1.44 kg/lit.

For determination of bulk density the container size shall be as given below:

| Size of particle | Nominal capacity (litres) | Inside dia (mm) | Inside height (mm) | Thickness of metal (min) (mm) |

| 4.75 mm and under | 3 | 150 | 170 | 3.15 |

| Over 4.75 mm to 40 mm | 15 | 250 | 300 | 4.00 |

| Over 40 mm | 30 | 350 | 310 | 5.00 |

Procedure:

(a) About 100 kg of aggregate sample should be dried in the room.

(b) Take the weight in kg of empty container + glass plate (Weight A).

(c) The container is to be filled with loose sand or loose aggregate i.e. sand or aggregate should be dropped in the container from about 5 cm height from top of container. Take the weight of container filled with sand or aggregate + glass plate (Weight B).

(d) Empty the container filled it with clean water upto the top ridge putt glass plate. There shall not be any air bubble. Take is weight (Weight C). All weight should be taken in kg.

Off room dry sand or aggregate = [B-A]/[C-A]

And voids percentage = [(Specific gravity – bulk density)/ Specific gravity ] x100

NON-DESTRUCTIVE TESTING OF CONCRETE STRUCTURE BY TAPPING

METHOD For testing low-grade concrete in unimportant constructions the strength of concrete may be determined either from its hardness when scratched with a metal “pencil” or a chisel, or from the character of the sound when struck with a hammer, or from the character of the mark left after a hammer blow.

The tapping method is not very exact but it is simple and can be easily applied for an approximate determination of the strength of concrete and in some cases is still used. On the concrete to be tested a smooth surface about 100 x 100 mm is chosen and cleaned with a metal brush. Then a hammer 300-400 gm in mass is struck against the concrete from elbow height directly or through a metal worker’s chisel placed at right angles to the tested surface. The size of the mark left the hammer or the chisel and the sound of the hammer stroke are indicative of the strength of concrete. Ten blows of average force are made at different points on the specimen. Results, exceedingly low, are disregarded. Approximate values of the strength of concrete obtained from these tests are given in the following table. The tapping method is used for an approximate determination of the strength of low-grade concrete, because the force of the blow and the accompanying sound vary greatly depending on subjective factors.

| Strength of concrete N/mm2 | Test Results | ||

| Blow of hammer (0.4 kg) upon concrete surface | Blow of hammer (0.4 kg) upon chisel placed at right angles to concrete surface | Scratching by Chisel | |

| Below 6 | Sound toneless. Deep dent with Crumbling Edges | Chisel is easily driven into concrete | Concrete cut easily and crumbles |

| 6 – 10 | Sound slightly toneless. Dent has smooth edges. Concrete crumbles | Chisel can be driven into concrete deeper than 5 mm | Visible scratches 1 – 1.5 mm deep |

| 10 – 20 | Sound clear whitish mark remains | Thin scales split off round the mark | Visible scratches no deeper than 1 mm |

| Over 20 | Sound ringing, Metallic, Mark-visible | Mark is not very deep | Barely visible scratches |

DETERMINATION OF WEIGHT PER CUBIC METRE AND AIR CONTENT OF FRESHLY MIXED CONCRETE

The measures for this test shall be as given below:

| DIMENSIONLA REQUIREMENTS FOR CYLINDRICAL MEASURES | ||||

| Nominal size of coarse Aggregate | Nominal capacity | Inside Dia | Inside height | Minimum Thickness of metal |

| mm | Cu.m | Mm | mm | mm |

| Upto 38 | 0.01 | 250 | 280 | 4 |

| Over 38 | 0.02 | 350 | 285 | 5.5 |

Calibration of measure. The measure shall be calibrated by determining the weight of water at room temperature required to fill it so that no meniscus is present above the rim.

Accurate filling of the measure may be secured by the use of a glass cover plate. The capacity of the measure in cubic meters shall then be obtained by dividing the weight of water (in gms) required to fill the measure by the unit weight of water, 1000 g/l.

Procedure: Determination of density. The measure shall be filled with concrete as soon as practicable after mixing. The representative sample of concrete shall be filled into the measure in layers approximately 5 cm deep and each layer shall be compacted by 38 cm long steel bar which shall have a ramming face of 2.5 x 2.5 cm square. The number of strokes per layer required to produce the specified condition will vary according to the type of concrete, but in no case shall the concrete be subjected to less than 60 strokes per layer for the 0.01 m measure or 120 strokes per layer for the 0.02 m measure.

The exterior surface of the cylinder shall be tapped smartly 5 to 10 times or until no large bubbles of air appear on the surface of the compacted layer.

After consolidation of the concrete, the top surface shall be struck-off and finished smoothly with a flat cover plate using great care to leave the measure just level full. All excess concrete shall then be cleaned from the exterior and the filled measure weighted.

Calculations: 1. Weight per cubic metre. The weight per cubic metre of concrete shall be calculated by dividing the weight of fully compacted concrete in the measure by the capacity of measure as determined above, and shall be recorded in kg/m .

- Air content. The air content shall be calculated by the formula: A= [T-W]/T x 100

or A = [V-V ]/V x 100

where, A = Air content (percent of voids) in the concrete T = Theoretical weight of the concrete, in kg/m , computed on an air free basis W = Weight of concrete produced per batch in m V = Volume of concrete produced per batch in m V = Total absolute volume of the component ingredients in the batch, in cubic metre

source: internet